COMPANY PROFILE

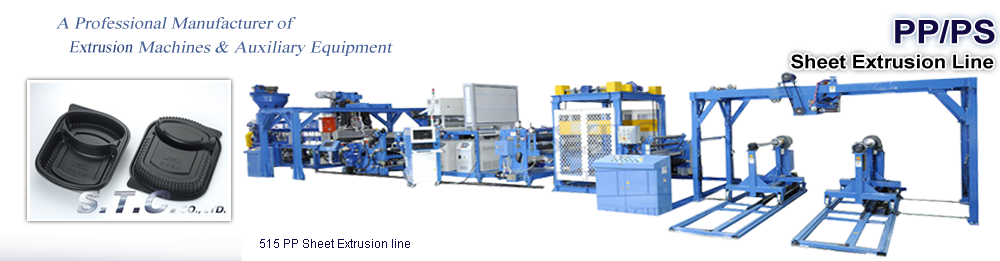

Shang Ta Chia Industrial Co., Ltd. was established in 1984. The former company name was Ta Chia Plastic Fiber Industrial Co., Ltd. STC’s business cover extrusion machine, plastic extruder and products. In 1988, we specialized in designing and manufacturing of PP sheet extrusion line, PS sheet extrusion line, stationery sheet extrusion line, PP film extrusion line, PE film extrusion line, PVC sheet extrusion line, …etc. and got an excellent reputation for precise plant designs to meet customers’ requirements in this field.

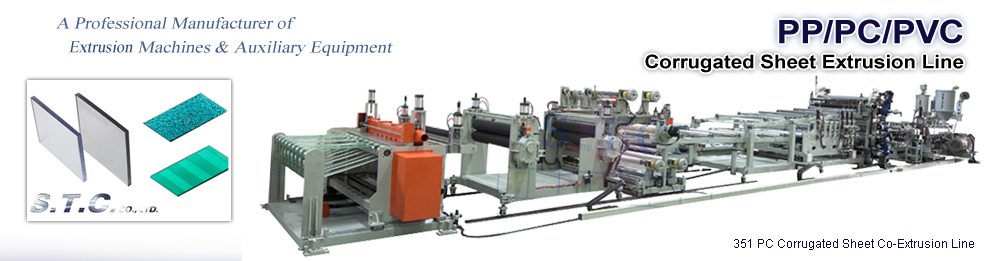

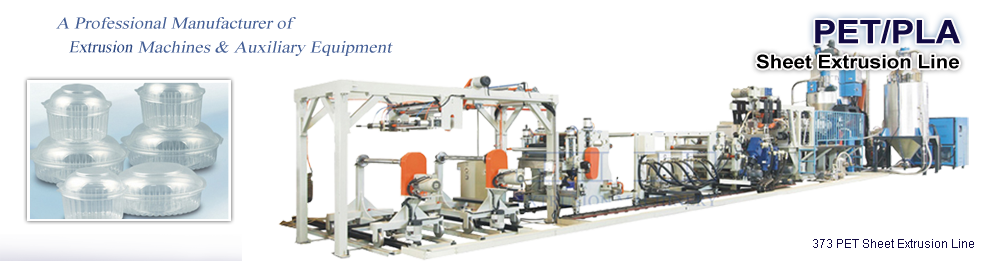

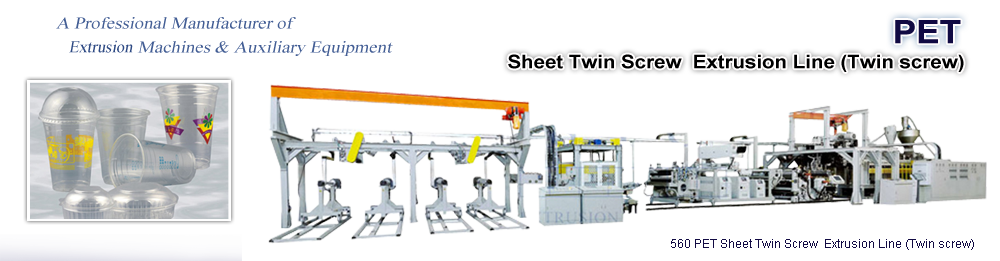

Since the company established, STC was devoted to technological research and development. In 1992, we manufactured PP hollow profile sheet extrusion line, PC hollow profile sheet extrusion line, multi-layer laminating extrusion line, high production PP/PS/PE/PC multi-layer sheet co-extrusion line, PET sheet extrusion line and upgraded the performance of the existent sheet extrusion lines and PP film extrusion line. The finished products are in various applications of house decoration, advertisement, exhibition, packing, electricity pipeline board, sky-light cover, anti static electricity board, stationery making, plantation field and vacuum/thermo forming purpose (disposable container) worldwide.

In 2020, a meltblown non-woven production line has been launched, which can produce meltblown non-woven fabrics for masks or filters.

STC is active in research and development, pursuing total customer satisfaction and providing superior quality, high production and profitable production machinery. All these create three-win among our customers, employees, and the company. Based on the best possible service concept, we provide the most comprehensive services for our customers, including machinery operation instructions and maintenance instructions. In the future, we will continuously strive for providing the exceptional total service, take advantage of advanced technology and lead toward the internationalization.

We pride ourselves on being a leader in the industry, driven by our commitment to excellence in research and development, manufacturing prowess, and unparalleled customer service.

Research and Development Technology

In an era defined by fierce competition, we firmly believe that consistent delivery of high-quality machines is the key to gaining customer trust.

Substantial capital and effort are invested in our R&D department.

Our team of experts specializes in machinery, electronic control systems, and material processing.

We value customer feedback, using it as a reference for mechanical improvements, and are dedicated to staying at the forefront of machine design technology.

By doing so, we not only provide our customers with a diverse range of high efficiency machines but also enhance the competitiveness of their products.

Manufacturing Capability

Our rich manufacturing experience and stable production capacity set us apart.

A well-formulated production plan, coupled with the advantages of modern and spacious facilities, significantly boosts our overall production efficiency.

We prioritize quality by insisting on the use of premium steel for long-term durability and precision in the tolerance range.

Skilled technical teams adeptly handle critical parts, utilizing precision processing equipment for cutting, welding, grinding, and deep hole drilling.

Thanks to our extensive manufacturing experience and key engineering process, the finished equipment from STC is on par with the recognized quality of German or Japanese manufacturing.

Customer-Centric Service

We understand the importance of catering to unique customer requirements.

STC offer highly customizable production solutions by adjusting parameters as needed.

Our team of highly trained and experienced engineers provides timely, state-of-the-art solutions with a focus on quality and CE conformity.

Our quality assurance practices involve regular vendor audits and objective verification of product quality to ensure customer satisfaction.

Quality Management

Total quality control is not just a policy at STC, it's a tradition.

We've obtained ISO-9001 certification, a testament to our unwavering commitment to quality control.

Our comprehensive quality standards span every stage of the manufacturing process, from incoming material inspection to in-process checks and final machine tests.

Regularly accepting quality certification inspections is our assurance to you.

Trust in STC is our customers' insistence, and manufacturing equipment that brings success to our customers is our commitment.

We welcome all customers who are willing to grow with us to further contact us.