Meltblown Nonwoven Fabric

[Meltblown Nonwoven Fabric]

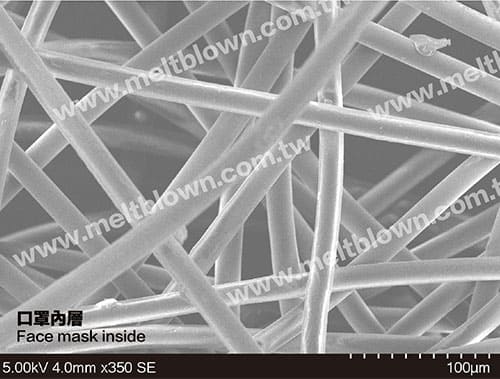

The melt-blown nonwoven fabric is known as the "heart of the mask", disperses molten plastic through high-speed hot air, and spins the polymer melt through the spinneret of the ultra-fine nozzle, making it a high-performance polypropylene melt-blown filter material. Fibers are extremely thinner than other materials.

Without increasing the loading of uses, through electrostatic electret technology, the static electricity is absorbed in the melt-blown non-woven fiber, it can absorb viruses and bacteria that have penetrated through the surface layer, thereby improving the filtering performance of masks and other filtering products.

It has ultra-fine fibers with shielding, filtering, oil absorption and thermal insulation properties. It has a wide range of fiber fineness and fiber diameters of up to 2 to 5 microns. These ultra-fine fibers can increase the number and surface area of fibers per unit area and can be used as mask materials , Air, liquid filter materials, thermal insulation materials, insulation materials, sound insulation materials, environmentally friendly oil-absorbing materials and wipe cloth and other fields.

Filter Products

Filter Products- Mask filtering

- Air purifier, air conditioning filter

- Filtration of fume and second-hand smoke

- Car air filtration

- Fabrication room filtration

Thermal Insulation Products

Thermal Insulation Products- Ski equipment, gloves: cold protection padding

Adsorption Products

Adsorption Products- River pollution prevention, environmental protection oil absorption, wipe cloth, etc.

| GSM Weight |

|---|

| 15gsm |

| 25gsm |

| 30gsm |

| 40gsm |

| 50gsm |

| Width |

|---|

| 175mm (Standard) |

| 150mm (Customization) |

| 165mm (Customization) |

| 170mm (Customization) |

| 185mm (Customization) |

| 190mm (Customization) |

| 200mm (Customization) |

| 210mm (Customization) |

| 230mm (Customization) |

| 235mm (Customization) |

| 240mm (Customization) |

| 245mm (Customization) |

| 250mm (Customization) |

| 260mm (Customization) |

| 73 CM (Customization) |

| Color |

|---|

| White |

| Black |

The outermost layer of the mask is spunbonded non-woven fabric, which is highly breathable and water-repellent, and the first is to prevent the contamination of droplets; the middle layer is a melt-blown non-woven fabric, which mainly filters the virus, bacteria, dust and droplets in the air. The layer is made of water needle non-woven fabric, which absorbs sweat and grease, and the soft fiber allows users to have an excellent wearing experience.

How to know if the mask is functional? You can find on the packaging whether the products have passed the National Standards of the Republic of China CNS. The common standards of masks are listed below and what they mean.

| CNS 14774 | Medical Face Masks |

|---|---|

| CNS 14775 | Method of test for evaluating the bacterial filtration efficiency (BFE) of medical face mask materials, using a biological aerosol of staphylococcus aureus |

| CNS 14776 | Method of test for resistance of medical face masks to penetration by synthetic blood (horizontal projection of fixed volume at a known velocity) |

| CNS 14777 | Method of test for air exchange pressure of medical face mask |

| CNS 14755 | Disposable dust respirators |

|---|---|

| CNS 14756 | Disposable dust respirators with activated – carbon |

- According to CNS-14775 test method, the bacterial filtration efficiency (BFE) of the mask must be above 95%.

- According to CNS14755-2003 "Disposable Dust Mask" Section 7.2 test method, Submicro particulate filtration efficiency (Submicro particulate filtration efficiency) 80%.

- According to CNS-14777 inspection method, differential pressure (Differential pressure) 5 mmH2O / cm2 or less.

- According to CNS-14776 test method, synthetic blood penetration: Pass pressure 80mmHg.

- According to CNS-10285 test method, flammability is level 1.